Over the course of my build career I have had many conversations with prospective and present clients. While everyone has dreams and ideas of how their final project should look, there are always those questions in the “middle” that are the sticky points.

- Let’s start with size – depending on the project, the answer to this question will determine multiple items in the quote.

- If this is a dining table, how many people do you want to sit at it on a regular basis?

What type of base are you looking for? Wood or steel are the usual choices that I have worked with. It is more economical and cost effective for both my client and myself to use a third party supplier for both. Once its determined which style is preferred then I will provide a link to the supplier and work with the client to choose the leg that allows the project to be constructed to specifications.

- If this is a dining table, how many people do you want to sit at it on a regular basis?

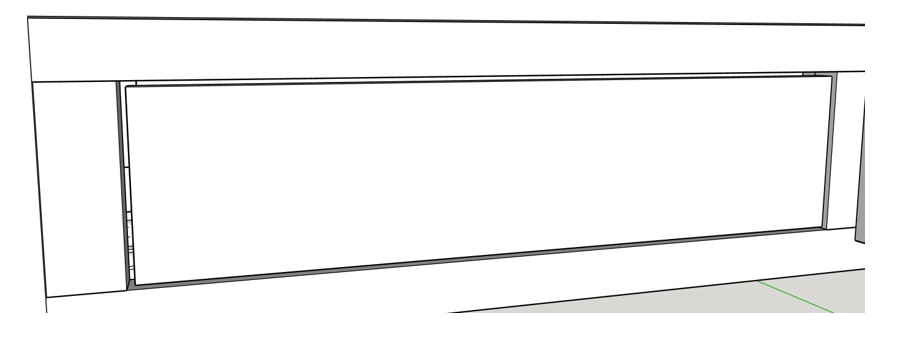

- If this is an Island, do you need drawers? If so, how many and how deep. The depth of the drawers will determine the depth of the apron.

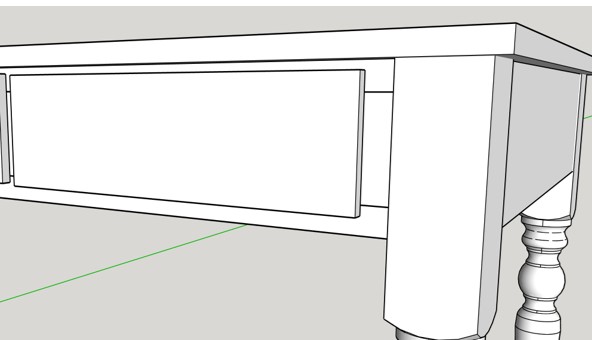

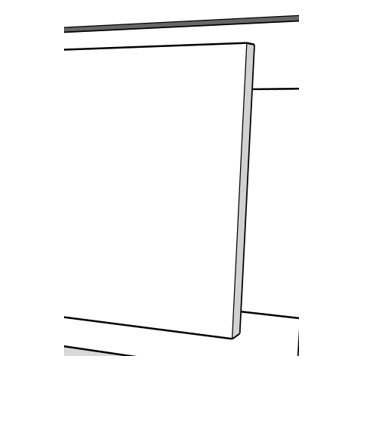

There is always a question as to what is meant by the “apron? The apron is installed at the top of the legs just below the top. This allows me to create slots where the drawers will fit. (An apron is also used to tie the legs together and form a skeleton for the table top or island top to rest on. )This also allows me to determine if the drawers are ‘Inset” or “overlay” Overlay meaning the drawer front will overlay or sit on top of the apron or the slot the drawers resides in

The apron is installed at the top of the legs just below the top. This allows me to create slots where the drawers will fit. (An apron is also used to tie the legs together and form a skeleton for the table top or island top to rest on. )This also allows me to determine if the drawers are ‘Inset” or “overlay” Overlay meaning the drawer front will overlay or sit on top of the apron or the slot the drawers resides in

- Inset means the drawer front will rest inside the drawer slot

- On the subject of drawers let’s consider the drawer slides. There are multiple options on the market however I prefer a soft close, under mount slide that allows the drawer to be open and not expose the drawer slide. What you pay for in the quality slides you save in labor. So the cost is a wash.

- What about doors? If this is an island, then how many doors do you want on each side?

- Will they be standard shaker doors are will they be a bit more fancy.

- Will they be painted or stained

- Do you need shelves inside the doors or will the cabinet be open

- Will you need sliding racks to hold your appliances and keep them out of sight until you are ready to use them

- Let’s talk about wood choices – There are so many options out there to choose from and it really determines what matches best in your home or office.

- First, I do not get any wood, other than plywood, from local box stores. All my wood comes from lumber mills. This option gives you and I better choices, prices and options.

- How do you want the wood to speak to you. By that I mean how loud do you want your grain to be.

- Ash is very hard but the grain is very loud or pronounced. – Takes any stain very well

- Maple on the other hand is hard, beautiful and fairly quiet – Takes any stain very well

- Red and White oak grains are somewhere between the two as far as grains are concerned. – Takes any stain very well

- Black Walnut, which is really dark brown with some beige mixed in, us another quiet grain but absolutely beautiful. I do not stain this wood because you do not want to hide the beauty. I apply six coats of clear polyurethane

- Cherry is another wood that doesn’t get stained. While it’s the softest of these hardwoods, it is very durable and is beautiful in its own right.

- If you decide to paint something, then Poplar is the wood choise to go with. It is considered the softest hardwood and the hardest softwood. Because it can have a purple or green tint It’s best painted rather than stained.

- Now for probably the most important item to decide on – Color – things to consider

- What is your house of office color scheme – we do not want to clash

- What wood did you choose – how loud or quiet grain do you prefer

- What other furniture do you have in you location that you want to compliment or accent

- Important part here – If you are trying to match a very old piece keep in mind the color on that piece has faded, gotten dirty/oily over the years. Color matching is the hardest part of the build

- Pictures are worth a thousand words

- I always recommend that clients look on line for examples of what they want the final product to look like. I may take multiple pictures that identify different aspects that you want.

- What’s next

- I will take the pictures and your dimensions and start putting the ideas together into my design program.

- I will design it as close as possible to what you have asked for so you can see it. I will send the drawings via email for your approval. It could take a few updates to get where we want to be but that is normal.

- Once the design is complete then I begin the quote process. If the wood species has not been chosen yet, then I will create the quote with multiple species.

I have created a spreadsheet that contains 2 sections. The first section allows me to insert line items for the wood (priced per board feet), any hardware such as hinges, drawer slides, screws, etc… These line items calculate sales tax. This section also includes line items for miscellaneous which would include any small items that I may need during the build. It also includes a line item for delivery. The other section is where I calculate the labor hours needed to complete the project. The final price that I will give to the client includes sales tax.

These two sections are calculated together to give me the total cost for the project. I take this calculation minus the sales tax, divide it in half and create 2 invoices in my Online QuickBooks software. Each invoice represents 50% of the final cost. The first invoice is sent to the client that represents the deposit needed for me to purchase materials and start the project. The second invoice represents the balance and is due upon completion of the project.

It doesn’t stop there – Once the calculations are complete, they transfer to a section that is needed to calculate the sales taxes I will need to pay to the state that have been collected. Another section calculates my total profit for income tax reporting. Using this same profit calculation, I calculate a 10% total for a donation I make for every project that I build.

It takes a lot of Parts, Pieces and Colors to put a project together and bring the clients vision/dream to life.