How to know if your wood is dry enough to use on your project

I’m always concerned with the amount of moisture in the wood I purchase. Before I begin a project I always check the woods moisture level. Wood moves as it is, but if there is too much moisture, the joints won’t stay matched. There is also a danger that the finish won’t dry correctly. But most of all the cuts won’t continue to match from one day to the next.

Air Dried or Kiln Dried, what is the difference?

Air dried is just that. Let it sit in a shed or barn or even outside and let the wind and sun dry it out. This process can take quite some time so patience is a virtue.

The other option is kiln dried. Kiln dried lumber is heated to remove the moisture with a goal of having 6 – 8% moisture content when finished. The lumber purchased at most brick and mortar lumber stores is kiln dried prior to the store receiving it.

How to use a Moisture Meter

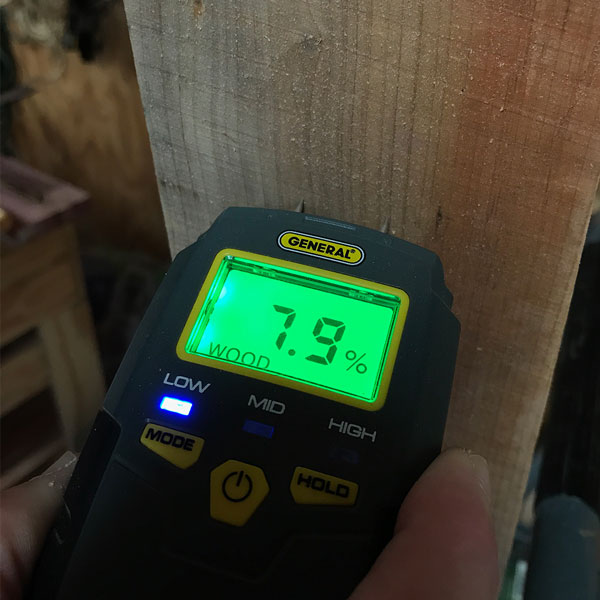

My goal is to get wood as close to 8% moisture content prior to building. Because I purchase rough lumber from a lumber mill, I have to let it dry in my enclosed wood rack or in the shop. I own a General MMD4E moisture meter that allows me to measure the amount of moisture in the wood.

Below is a demonstration of the meter being used to show the moisture in 2” cedar that has been drying for a couple of weeks.

Below is a demonstration of some 3” black walnut that is nowhere near dry enough to work with.

Which is best? Air or Kiln Dried?

There are lots of opinions on using Air dried or Kiln dried wood. Which one is the right one? I think both – depending on your project. I always try to keep an inventory of rough poplar and oak in my rack and shop, air drying for future projects. But if I need to turn a project around quickly I need another option. I can buy wood from the brick front store or call a local mill to kiln dry it for me.

Why I buy rough lumber from a local mill

The most important reason I purchase rough lumber from the mill is the price. I can purchase an actual 1x8x96 oak at a board foot price of $1.20 per board foot or $9.60 per board.

Where a nominal, 1x8x96, piece of oak at the brick front store is $4.63 per board foot or $37.04 per board.

Nominal vs. Actual size lumber – There is a great article available on the Nelson Blog that gives a great explanation.

Acclimating Lumber

I often here the following questions: Does my wood need to acclimate to my shop before using? Can I just bring the wood into the shop and start building? These are questions that really do not have a right answer except – it depends. It depends on the specifies of wood as well as the project.

For a large project such as a cabinet or table made with oak or walnut, I like to bring all the needed air dried lumber into the shop. At least for a few days before building it should acclimate to the inside temperature.

If I need to grab a single piece of lumber in the middle of the project, I can use it as long as the moisture is within that proper range. Most of these items are going to be inside and will dry out quickly with the drier air inside.

For a toy or shelf built of poplar and will be painted, I’ll bring it into the shop and start building with it.

For outside items such as cedar Adirondack chairs or tables, I will start building as soon as I bring home from the mill unless it is wet to the feel. Cedar dries fast enough and it’s going to be outside where the moisture content will be changing on a regular basis.

Final Thoughts

Keep in mind that any wood items brought into the house will dry and shrink in the winter and gather moisture and swell in the summer. To prevent shrinking – keep humidifiers running in the winter. A dehumidifier will reduce swelling in all your furniture joints in the damp summer air.

BTW – your skin will tell you if the house is too dry. If it’s too dry for you, it’s too dry for your furniture.